Fixed vs. Mobile Axle Load Scale Which Suits Your On-Site Weighing Needs

On-site weighing is important in fields like logistics, construction, and mining for maintaining safety, adhering to regulations, and managing costs. The primary equipment for these tasks is axle load scales. There are fixed axle load scales, which are placed in permanent locations, and mobile ones which can be moved and are more flexible. This piece will help you choose the appropriate weighing equipment for your site needs by focusing on these two kinds of axle load scales.

What Even Is an Axle Load Scale?

An axle load scale checks the weight of each axle of a vehicle (e.g., trucks, trailers, construction equipment) using pressure sensors which convert weight to a readable form. Compared to traditional weighbridges, axle load scales are practical for three reasons:

- Take up less space since they do not have huge concrete pads.

- Weigh specific axles, which are important for overloading regulations.

- Fit in tight spots such as construction sites, yard entrances, or mines.

Widely applied across diverse sectors, these scales are essential for accurately weighing various materials.

Fixed Axle Load Scales

Key Features

Construction: Built using heavy-duty steel frames, tough digital displays (built for years of daily use), and weatherproof sensors.

Installation: Will require basic wiring and a level, reinforced site (often with concrete). Expect 1–2 days for setup.

Advantages:

- Perfect for compliance checks because of super high accuracy.

- Minimal maintenance costs.

- Extremely high traffic seamlessly and instantly.

Fixed axle load scales are great for high-volume, stationary weighing situations. During a seamless weighing process at a regional logistics hub, these scales are positioned at the entrance of the warehouse. Weighing systems are setup so that trucks drive onto the scale and, without any interruptions, their weights are recorded in 60 seconds and it is calculated with absolute accuracy. For heavy continuous use, the scales are made tough. For the last eight years of use without any interruptions, thanks to yearly calibrations, precise weighing has been ensured; this hub has been relying on the same scales. Facilities can use fixed scales to perform repetitive, consistent, and reliable weighing operations. Designed for established weighing points, fixed scales are ideal.

Mobile Axle Load Scales

Key Features

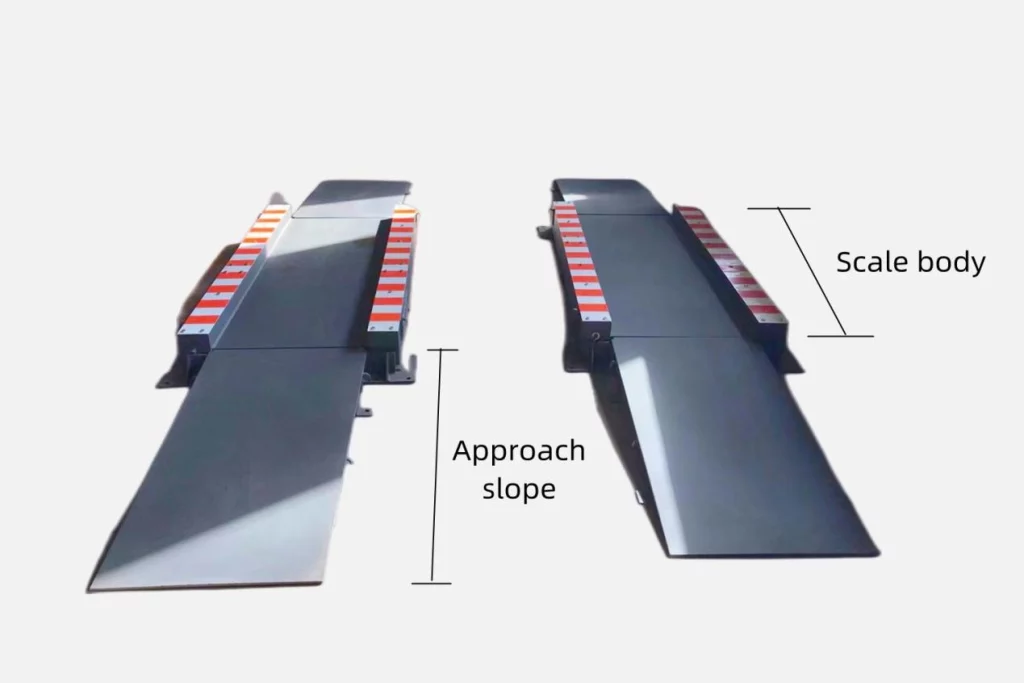

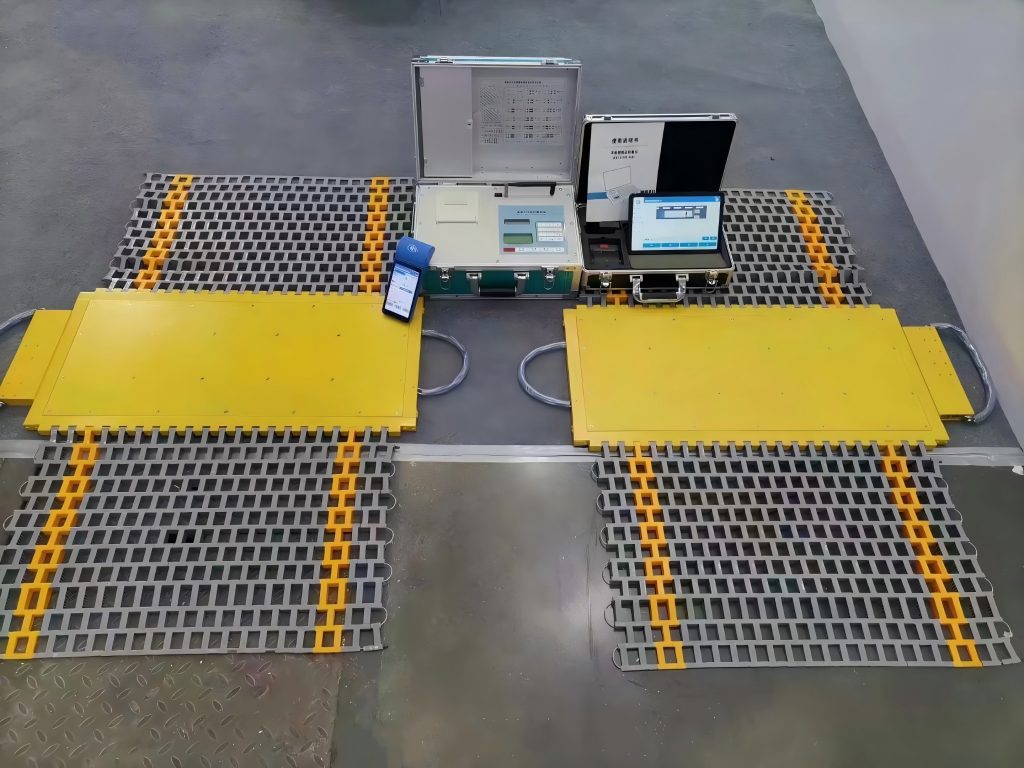

Design: Battery-powered (most less than 50 lbs.), foldable, and lightweight. Some even come with carrying cases.

Setup: Unfold, connect the display, and you’re ready in 10–15 minutes. No ground anchors, no wiring.

Advantages:

- Flexible (use at job sites, roadside checks, or temporary depots).

- Low upfront cost (no installation fees).

- Easy to store (hide away).

Mobile axle load scales excel in dynamic weighing scenarios. Ideal for construction sites with multiple job locations, they can be easily transported by pickup trucks or trailers, enabling on-site weighing of delivery trucks at each new project. Their portability also makes them suitable for temporary road maintenance projects, agricultural operations with mobile equipment, and logistics companies that need to weigh vehicles at various depots. This flexibility eliminates the need for multiple fixed scales, providing a cost-effective solution for businesses with changing weighing requirements.

How to Choose: Fixed vs. Mobile

To help you make an informed decision, we’ve compiled a detailed comparison of fixed and mobile axle load scales across key parameters. This breakdown will highlight the distinct advantages and ideal use cases for each type, ensuring you choose the weighing solution that best fits your operational needs.

| Factors | Fixed Axle Load Scale | Mobile Axle Load Scale |

| Weighing Frequency | 5+ times per day at the same spot | Less often or move locations |

| Site Stability | Permanent spot | Temporary spot |

| Budget Focus | Lower long-term costs (install once) | Lower upfront costs (no setup fees) |

| Accuracy Needs | Precision (±0.1% – ±0.5%) | Basic accuracy (±1% – ±3%) |

| Environment | Ideal for controlled, sheltered areas | Better suited for outdoor, variable weather conditions |

| Damage Resistance | High | Moderate |

Other Key Purchasing Considerations

- Verifying Certification Compliance: Check that the axle load scale has the relevant certification from authorities such as the NTEP in the U.S. or comparable bodies in other countries. Certification ensures that the scale is accurate and legally compliant, which is crucial for dependable performance and meeting regulatory requirements.

- Evaluation of Data Management Capabilities: Preference should be given to models with more advanced data management, specifically, data storage and retrieval. Self-contained systems that archive weighment data facilitate record-keeping and simplify data analysis and the data integration processes with other management systems.

- Presence of Self-Diagnostic Capabilities:These are certain to be valued as they permit automation of the problem identification processes, specifically, the identification of sensor failures, power inconsistency, and calibration deviation. These problems can be addressed to uphold the performance of the scales and prevent continued underperformance.

- Evaluation of After-Sales Support: Enumurate to the relevant your primary ub is for your scale to provide the relevant needed service to the determined service level.

Conclusion

There is no universally “better” scale; only the best one for your requirements. If you are weighing the same location every day, choose a fixed axle load scale. If your weighing activities are more dispersed, choose a mobile axle load scale.

If you need a second opinion, consulting a supplier helps—for professional advice, turn to Bincen. Our expert team is dedicated to addressing your needs and recommending the best model based on your location and weighing frequency.