The 2025 Weighbridge Buying Guide Everyone’s Sharing: Best Picks for Mining, Recycling, Logistics & Food Sites

Different industries utilise weighbridges for a wide variety of purposes. Mud and 90-ton trucks versus clean floors and strict hygiene regulations. This is why buying “just any weighbridge” usually ends up causing repairs, downtime, and/or accuracy issues.

- Dirty site → Pitless

- Fast traffic → Pit type

- Need clean records → Digital or Smart

Every week, we witness the everyday challenges faced by weighbridge manufacturers like you.

With that in mind, we provide you with a real-world, elementary, and highly practical guide without the use of complex terminology.

What Weighbridge Is the Best Pick for Mining, Recycling, Logistics & Food Sites

This table gives you a quick snapshot of the top risk for each industry and the type of weighbridge that handles it best.

| Industry | Daily Conditions | Biggest Risk | Best Weighbridge Type | Why It Works |

| Mining | Mud, heavy trucks, harsh weather | Damage from impact + hard cleaning | Pitless, fixed, heavy-duty deck | Open space under deck makes cleaning and repairs easier |

| Recycling | Waste, dirt, debris buildup | Sensors getting blocked | Pitless, open-structure deck | Debris falls through instead of blocking sensors |

| Logistics | High traffic, time pressure | Slow truck flow | Pit type + digital + smart automation | Drive-through weighing speeds up operations |

| Food Processing | Hygiene control, water washdown | Contamination + rust | Pit type + closed deck + stainless options | Flush-to-ground design is easier to keep clean |

Dirty site = Pitless.

High-traffic site = Pit type.

Clean or hygiene-sensitive site = Closed deck.

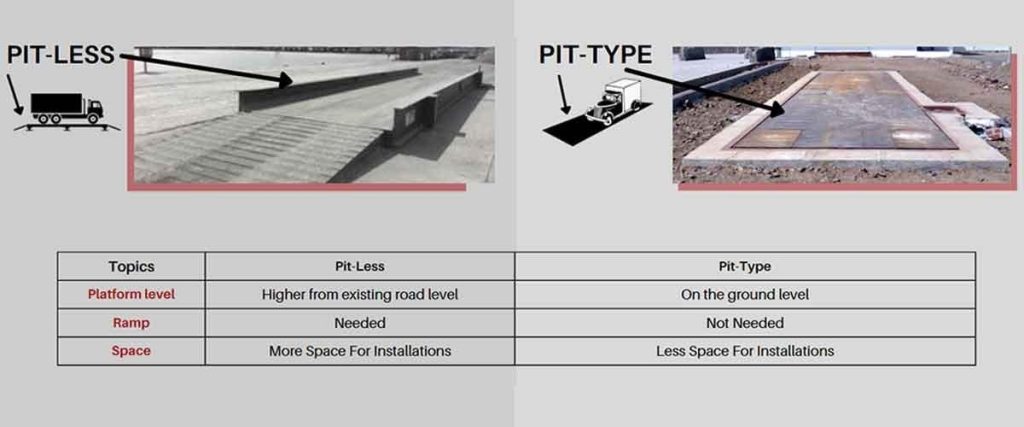

1. Pitless vs Pit Type Weighbridges: The Most Important Decision

Pitless Weighbridges (Above-Ground)

Tonnage: 30–120 tons

Where it shines: mining, recycling, construction yards

Pros

- Lower installation cost

- Much easier to maintain

- Works even on uneven or rough ground

- No drainage problems

Cons

- Needs ramp space

- Slower traffic flow

Best when: your environment is messy, rough, or constantly changing.

Pit Weighbridges (In-Ground)

Tonnage: 50–150 tons

Where it shines: logistics, food factories, distribution centers

Pros

- Fast drive-through weighing

- Small footprint

- Cleaner, more professional on-site look

- No ramps needed

Cons

- Higher civil cost

- Requires reliable drainage

- Harder to access for repairs

Best when: site speed and neat layout really matter.

2. Portable Weighbridge vs Axle Scale — Not the Same Thing

3. Digital vs Standard Weighbridge— Think About Data, Not Just Weight

Standard Weighbridges

Tonnage: 30–120 tons

Pros

- Simple

- Affordable

- Easy to run

Cons

- Manual entries → human errors

- Not great when scaling up operations

Best for: small yards or low-traffic sites.

4.Smart / Unmanned vs Traditional — Automation Makes a Difference

Traditional (Manual)

Pros

- Low cost

- Easy to understand

Cons

- Depends on the operator

- Risk of inconsistent data

Best for: simple operations where speed isn’t critical.

6. Mobile vs Fixed Weighbridge — Do You Need to Move It or Not?

Final

| Industry | Best Setup | Reason |

| Mining | Pitless + Fixed heavy deck | Handles dirt + impact |

| Recycling | Pitless + Open deck | Avoids debris buildup |

| Logistics | Pit type + Digital + Smart | Speed + accuracy + automation |

| Food | Pit type + Closed/stainless | Hygiene + easy washdown |

Why Bincen Is Worth Considering

If you’re shortlisting weighbridge manufacturers, Bincen is a solid starting point.

They’re known for:

- Practical, long-lasting steel decks

- Both pit and pitless options

- Portable + mobile solutions

- Digital and smart weighbridge systems

- Clear installation drawings and support